Industrial robots have become an integral part of modern manufacturing facilities, revolutionizing the way tasks are performed in various industries. These machines are designed to work efficiently, accurately, and tirelessly, often handling repetitive and dangerous tasks that can pose risks to human workers. However, ensuring the safety of these robots is paramount to prevent accidents and maintain a secure working environment. In this article, we will explore the essential safety features that industrial robots should have to operate effectively and protect both the machines and the workers.

**Physical Barriers and Enclosures**

One of the fundamental safety features for industrial robots is the presence of physical barriers and enclosures. These barriers serve as a protective shield around the robot’s work area, preventing accidental contact with moving parts or tools. By restricting access to the robot’s workspace, barriers enhance the overall safety of the working environment and reduce the risk of injuries. Additionally, these enclosures can be equipped with sensors that automatically stop the robot when breached, further enhancing safety measures.

**Emergency Stop Buttons**

Another critical safety feature that industrial robots should have is an emergency stop button. This button provides a quick and easy way to halt the robot’s operation in case of an emergency or when an unsafe situation is detected. By pressing the emergency stop button, operators can immediately stop the robot’s movements, preventing any potential accidents or injuries. It is essential for these buttons to be easily accessible and clearly labeled to ensure prompt action during an emergency.

**Safety Sensors and Vision Systems**

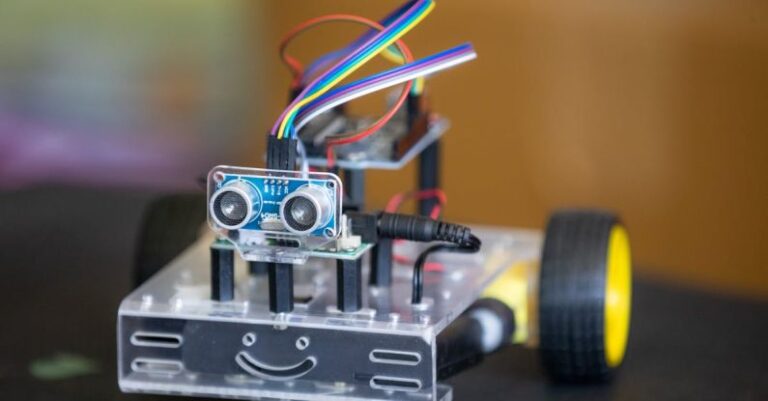

Safety sensors and vision systems are essential components that enhance the safety of industrial robots by detecting the presence of objects or people in the robot’s vicinity. These sensors can be used to create virtual safety zones around the robot, triggering an immediate stop if an object enters the designated area. Vision systems, on the other hand, provide real-time monitoring of the robot’s surroundings, allowing it to adjust its movements to avoid collisions or accidents. By integrating safety sensors and vision systems, industrial robots can operate more safely in dynamic environments.

**Collaborative Robots (Cobots)**

Collaborative robots, or cobots, are designed to work alongside human operators in a shared workspace, enabling closer interactions between robots and humans. These robots are equipped with advanced safety features such as force and torque sensors that can detect any unexpected contact with humans and immediately stop the robot’s movements. Cobots are programmed to operate at reduced speeds when working in close proximity to humans, ensuring a higher level of safety and reducing the risk of accidents.

**Risk Assessment and Safety Standards Compliance**

Prior to deploying industrial robots in a workspace, conducting a thorough risk assessment is crucial to identify potential hazards and implement appropriate safety measures. It is essential to assess the specific tasks that the robot will perform, the surrounding environment, and the potential risks associated with human-robot interactions. Additionally, ensuring that industrial robots comply with relevant safety standards such as ISO 10218 and ISO/TS 15066 is essential to guarantee safe operation and minimize risks in the workplace.

**Safety Training and Procedures**

In addition to having robust safety features in place, providing adequate training to operators and establishing clear safety procedures are vital aspects of ensuring the safe operation of industrial robots. Operators should be trained on how to operate the robots safely, how to respond to emergencies, and how to troubleshoot common issues. Establishing protocols for regular maintenance, inspection, and testing of safety features is also essential to maintain a safe working environment.

**In Summary**

Safety is a top priority when it comes to industrial robots, and incorporating essential safety features is crucial to prevent accidents and ensure a secure working environment. Physical barriers, emergency stop buttons, safety sensors, vision systems, collaborative robots, risk assessments, safety standards compliance, safety training, and procedures are all integral components that contribute to the overall safety of industrial robots. By implementing these safety features and practices, manufacturers can maximize the efficiency of their operations while prioritizing the well-being of their workers.