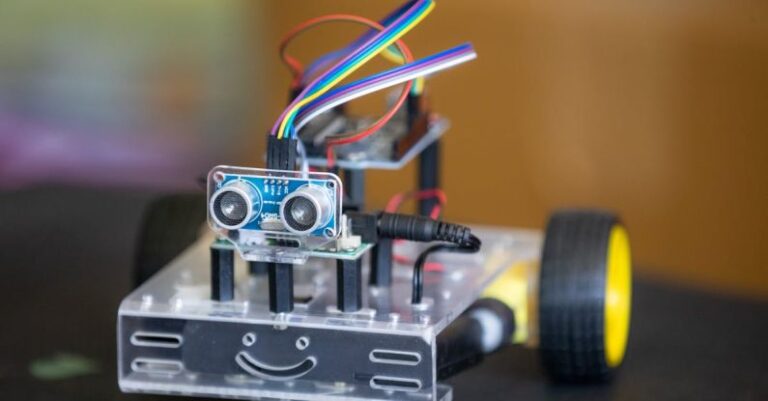

Robotics and automation have revolutionized the manufacturing industry in recent years, offering a myriad of benefits to businesses looking to enhance their efficiency and productivity. The integration of robots in manufacturing processes has significantly transformed the way products are made, leading to improved quality, increased output, and reduced costs. With advancements in technology, the question arises: Can robots further improve manufacturing efficiency? Let’s delve into the potential advantages of robotics in manufacturing and how they can continue to drive progress in this sector.

### Enhanced Precision and Accuracy

One of the key benefits of using robots in manufacturing is their exceptional precision and accuracy. Unlike human workers, robots are programmed to perform tasks with consistent precision, minimizing errors and ensuring high-quality output. This level of accuracy not only leads to a reduction in defects and waste but also enhances overall product quality, meeting the stringent standards of modern manufacturing processes.

### Increased Production Speed

Robots are capable of working at a much faster pace than human workers, leading to a significant increase in production speed. By automating repetitive and time-consuming tasks, robots can streamline manufacturing processes and boost output levels. This enhanced production speed allows businesses to meet growing demands efficiently and capitalize on opportunities for scaling their operations.

### Improved Workplace Safety

Safety is paramount in any manufacturing environment, and robots play a crucial role in enhancing workplace safety for employees. By taking over hazardous or physically demanding tasks, robots help reduce the risk of workplace accidents and injuries. This not only safeguards the well-being of workers but also minimizes downtime and associated costs resulting from workplace incidents.

### Flexibility and Adaptability

Modern robots are designed to be highly flexible and adaptable to different manufacturing requirements. With the ability to be reprogrammed for various tasks quickly, robots offer a level of versatility that is unmatched by traditional manufacturing methods. This adaptability enables businesses to respond swiftly to changing market demands and optimize their production processes to stay competitive in dynamic industries.

### Cost Savings and Efficiency

While the initial investment in robotics technology may seem significant, the long-term cost savings and efficiency gains justify the expenditure. Robots can operate 24/7 without the need for breaks, holidays, or overtime pay, leading to increased productivity and reduced labor costs. Additionally, robots can optimize resource utilization, minimize material wastage, and improve energy efficiency, resulting in overall cost savings for manufacturing businesses.

### Integration of AI and Machine Learning

The integration of artificial intelligence (AI) and machine learning algorithms in robotics has opened up new possibilities for enhancing manufacturing efficiency. AI-powered robots can analyze vast amounts of data in real-time, optimize production processes, and make predictive maintenance decisions to prevent downtime. By leveraging AI and machine learning capabilities, manufacturing businesses can achieve higher levels of operational efficiency and productivity.

### The Future of Manufacturing Efficiency

As technology continues to advance at a rapid pace, the future of manufacturing efficiency looks increasingly promising with the integration of robots and automation. Industry 4.0 initiatives are driving the adoption of smart manufacturing technologies, where interconnected systems and intelligent robots work together seamlessly to optimize production workflows. The ongoing development of collaborative robots, known as cobots, further enhances the synergy between human workers and robotic systems, fostering a harmonious work environment that prioritizes efficiency and innovation.

### Embracing a Robotic Future

In conclusion, the role of robots in improving manufacturing efficiency is undeniable, and their potential to drive further progress in the industry is vast. By harnessing the capabilities of robotics, businesses can enhance precision, increase production speed, improve workplace safety, achieve cost savings, and adapt to changing market dynamics with agility. As manufacturing continues to evolve, embracing a robotic future is not just a choice but a necessity for businesses looking to thrive in a competitive marketplace. The integration of robots in manufacturing processes represents a transformative shift that promises to redefine efficiency standards and unlock new opportunities for growth and innovation.